Resources

PPAP in Manufacturing – What It Is and Why It Is Important

PPAP is the industry’s most trusted framework for proving a supplier can consistently build high-quality parts that meet every OEM specification. Ultimately, it validates the full manufacturing process, reduces risk, and builds confidence before mass production begins.

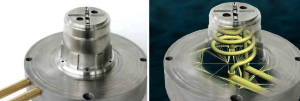

Conformal Cooling Inserts – Enhancing Part and Mold Quality

Conformal cooling inserts revolutionize thermal control in insert molding by enabling faster, more uniform cooling across complex geometries. This article explores their design, benefits, and applications in modern manufacturing.

CNC Machining vs Injection Molding

CNC machining and injection molding serve distinct roles in modern manufacturing. This article compares both processes in terms of cost, precision, and scalability to help you choose the right fit for your production goals.

Metal Surface Finishing: Enhancing Appearance and Performance

Metal surface finishing enhances durability, wear resistance, and aesthetics while ensuring compliance with strict industry standards. This article reviews key techniques, challenges, and how ITD Precision delivers excellence in finishing solutions.

Core and Cavity in Insert Molding – How to Make the Right Choice

The core and cavity are the heart of insert molding, directly controlling geometry, strength, and performance. This article explores their design, challenges, and ITD Precision’s optimized solutions for reliable, high-volume manufacturing.

Radial vs Orbital Riveting: Differences and Making the Right Choice

This article compares radial and orbital riveting, two high-precision cold-forming techniques used in modern manufacturing. It explores their mechanisms, advantages, and ideal use cases to help engineers choose the right solution for durable and efficient assemblies.

Flow Marks – What They Are and Prevention During Insert Molding

Flow marks are more than cosmetic flaws in insert molding; they often point to flow inconsistencies, poor gate design, or thermal imbalances. This article reviews what causes flow marks and outlines proven techniques to prevent them, such as insert preheating, optimized injection speeds, and surface treatments. Learn how ITD Precision eliminates flow marks through advanced tooling, conformal cooling, and real-time quality monitoring.

Types of E-Coating: Advantages, Applications, and Process Guide

E-Coating, short for electrophoretic coating, is a precise and environmentally friendly method for finishing metal components. This article explores how E-Coating works, its common types—like cathodic epoxy and anodic acrylic—and why manufacturers choose it for corrosion resistance, uniform coverage, and high-volume production. Discover how ITD Precision’s integrated manufacturing approach delivers tailored E-Coating solutions for every application.

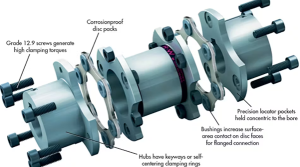

Disk Pack Couplings: High-Precision Torque Transmission

This article introduces disk pack couplings as essential components for high-precision torque transmission, especially in industries like aerospace, energy, and robotics. It covers how disk pack couplings accommodate misalignment while maintaining torsional rigidity, outlines their key design features, materials, and manufacturing processes, and explores emerging trends such as smart sensors and lightweight composites.

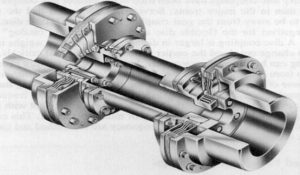

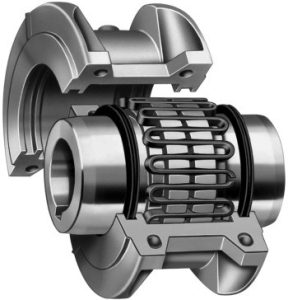

Flex Couplings – A Guide for Buyers and Manufacturers

Flex couplings play a critical role in connecting rotating equipment and managing misalignment. This article explores how they work, their types, design considerations, and why ITD Precision is your trusted partner for precision-manufactured flex couplings.

Disk Pack: Anatomy of a High-Performance Transmission Element

This article explores the anatomy, materials, design, performance features, and manufacturing considerations of disk packs. Thus, providing insights for OEMs, engineers, and manufacturers looking to source or develop high-reliability torque transmission components

Conformal Cooling vs Conventional Cooling During Insert Molding

Conformal and conventional cooling are key methods for managing heat in injection and insert molding processes. This article compares both approaches, examining their design, thermal efficiency, and impact on cycle time, part quality, and tooling complexity. Learn which cooling strategy offers the best performance for insert molding applications and how conformal cooling changes the game in modern mold design.