SERVICES

Services

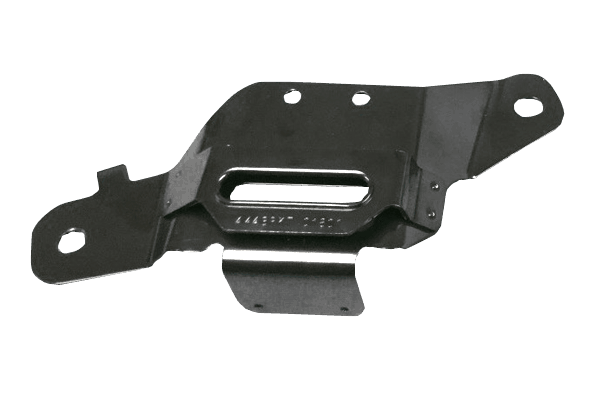

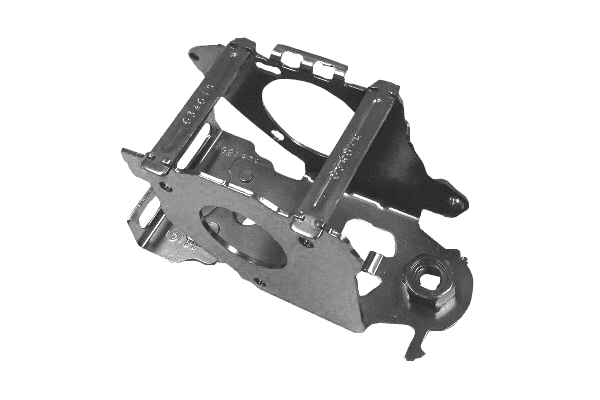

Metal Stamping

ITD Precision delivers contract metal stamping and precision stamping services with world-class quality and value.

We hold ISO/TS certification and also offer design assistance for metal stamping products. Our rapid turnaround on production tooling and prototyped parts sets us apart. With a capacity ranging from 35 to 400 tons, we provide complete support, as well as contract supply. This includes metal stamping, machining, finishing, plating, welding, and also assembly. Many of the world’s most demanding users of stamped metal components rely on our services.

Heat Treating

ITD’s austemper process offers significant benefits over the conventional oil quench and temper method. Generally, this process is ideal for metal stampings that require the highest level of distortion control. We quench the part from the proper austenitizing temperature directly into a liquid salt bath. The temperature of this bath ranges between 590 to 710 degrees Fahrenheit.

E-coating

Our Therma-Tron-X Econ-E-Coat Paint System features an SST, slide rail square transfer, system conveyor design. The line also includes pre and post water treatment systems, an automatic chemical feed system, and a state-of-the-art data management system.

Insert Molding

Light Assembly

ITD Precision offers a wide variety of value added automated assembly operations. Our engineering staff will design and manufacture the special equipment and also fixtures to deliver stampings with the added components and features ready for the assembly line

Quality Systems