The core and cavity constitute the master geometry of the mold, dictating every dimensional and functional aspect of the encapsulated assembly. Their design directly governs polymer flow dynamics, interfacial stress distribution, and final part performance. In insert molding, precision-engineered nesting within these components is critical to immobilize the insert against injection pressures and thermal shifts. Inadequate design induces failure through delamination, sink formation, or insert displacement, compromising structural integrity in high-stakes applications. This article highlights the concepts of core and cavity in insert molding, including selection factors, common design challenges, and best practices.

What Are Core and Cavity in Insert Molding?

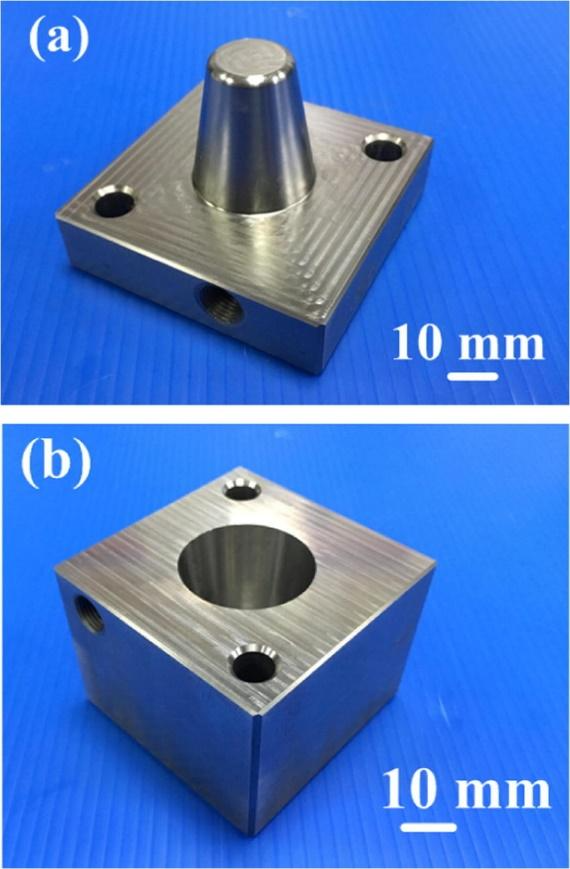

The cavity is the female half of the mold tool, essentially a negative impression machined into a block of hardened steel. As a result, it forms the external surfaces, contours, and overall shape of the final molded part. In insert molding, the cavity must also be designed to interface perfectly with the core. Moreover, the parting line where these two halves meet must form a tight seal to prevent plastic leakage, or flash. This condition is important, especially around the insert component. The design and finish of the cavity are paramount for achieving the required surface quality and aesthetics.

Core-Cavity Relationship

Both core and cavity function as a unified kinematic system to define part geometry. The cavity forms external surfaces, while the core shapes internal features and critical wall thickness, as illustrated in the figure below.

Polymer flows into their negative space, with cavity finish dictating aesthetics and core geometry forming functional internal structures. The accuracy of this interface, supported by rigorous thermal control and structural rigidity, is fundamental to producing dimensionally stable, high-performance components free of defects.

Key Factors in Choosing Core and Cavity Configurations

Ejection System Design

Ejection system design is integral to core functionality in injection molding. Moreover, the strategy must ensure part integrity and mold protection. Factors such as ejector pin type, size, and placement calculations depend on part adhesion and geometry. For delicate features, blade or sleeve ejectors distribute force to prevent distortion or damage. The system must operate with perfect uniformity and timing, ejecting only after adequate cooling to avoid part deformation or structural failure. Ejection is fundamental to dimensional accuracy and production.

Production Volume and Tooling Longevity

Production volume dictates both core and cavity material selection and treatment. Where low-volume runs utilize cost-effective aluminium for prototyping and high-volume production demands premium hardened steels like H13, capable of enduring millions of cycles. Strategic investment in tooling longevity minimizes wear, resistance, and downtime. Thus, ensuring consistent part quality and dimensional stability throughout the tool’s operational lifespan.

Part Geometry and Complexity

Part geometry dictates core and cavity design complexity. Undercuts require side actions, lifters, or unscrewing mechanisms integrated into the core. Draft angles are essential on both tool halves to facilitate ejection and prevent surface damage. Parting line placement critically influences mold function, machining cost, and final part appearance. Strategic design of these elements ensures manufacturability, reduces wear, and maintains part quality throughout the tool’s lifespan.

Insert Type and Nesting Requirements

In insert molding, the core and cavity design must accommodate, locate, and secure the insert with absolute precision. The cavity or core block must be machined with meticulous nesting features, pockets, datum locators, and support pillars. These design features hold the insert rigidly against the forces of injection. The design must also account for the differential thermal expansion between the metal insert and the mold steel to prevent misalignment or damage at operating temperatures.

Thermal Management Strategy

Cooling channel designs are paramount to injection molding, directly impacting part quality, cycle time, and cost. Optimally placed conformal channels follow part geometry to ensure uniform heat extraction, preventing warpage, sink marks, and residual stress. Precise control of parameters such as channel diameter, pitch, and coolant flow is essential for efficient thermal management. Whereas, poor cooling in the core results in extended cycles, uneven shrinkage, and ejection difficulties. A scientifically engineered cooling system is the defining feature that elevates a prototype tool to high-volume production capability, ensuring dimensional stability and manufacturing efficiency.

Common Core and Cavity Design Challenges in Insert Molding

Thermal Expansion Mismatch

One primary design challenge in insert molding core and cavity design is mitigating the differential thermal expansion between the mold steel and the insert. The core and cavity, which expand significantly when heated by the molten polymer, can mechanically conflict with the insert, which has a different coefficient of thermal expansion.

Disrupted Thermal Management

The metal insert acts as a significant heat sink, creating a severe thermal imbalance within the mold. This disrupts the uniform cooling cycle, causing the polymer surrounding the insert to solidify last and shrink in isolation from the rest of the part.

Insert Stability During Injection

A critical design hurdle is immobilizing the insert against immense injection pressures. The insert’s mass and smooth surface offer a low-resistance path for the incoming polymer, which can easily displace it if the core’s locating feature, such as pins, clamps, or pockets, is not kinematically designed to withstand these forces.

Entrapped Air and Venting

The complex geometry created by the inset nested within the core and cavity drastically increases the risk of air entrapment. Traditionally, venting paths are often blocked, forcing air into pockets where it becomes compressed and superheated by the advancing flow front.

Best Practices for Core and Cavity Design

Conduct Finite Element Analysis (FEA) for Stress and Flow

This is the most effective upfront practice because it identifies potential failure points such as insufficient venting, bending cores, or imbalanced flow, before steel is ever cut. As this virtual validation prevents costly mold reworks and optimizes gate placement to ensure robust mold.

Utilizing Kinematic Coupling for Insert Nesting

This method eliminates over-constraint, ensuring the insert is perfectly located and repeatable while still allowing for the calculated thermal expansion differentials between the insert and mold steel.

Integrate Multi-Stage Ejection System

It is a practice that involves sequencing the ejection process. And it is considered the best approach because it distributes ejection forces evenly, preventing the high stress concentrations that cause part distortion or core pin damage, thereby protecting both the part and the mold.

Applying Surface Engineering and Coatings

These ultra-hard, low-friction coatings are effective because they drastically increase abrasion resistance against filled polymers, enhance release properties to reduce ejection forces, and provide corrosion resistance against harsh processing materials.

How ITD Precision Optimizes Core and Cavity for Insert Molding

ITD precision optimizes core and cavity design for insert molding through a tightly integrated engineering approach, beginning with in-house tooling. Our in-house tooling solutions include CAM/CAD, CNC machining, and thermal management solutions like conformal cooling and real-time monitoring. Additionally, utilizing advanced quality systems, such as CMM, vision systems, and SPC, ensures precision and consistency. Our collaborative engineering approach ensures an optimal balance between material selection, cost, and manufacturability. Thus, delivering molds that are structurally robust, thermally efficient, and reliable across high-volume production. Contact us today and we can work together to optimize your molding process.