In the world of plastic molding, appearance matters just as much as performance. One common defect that manufacturers battle is flow marks, which are unwanted streaks or swirls that show up on molded parts. While they might look like a simple cosmetic flaw, flow marks can signal deeper issues in the molding process. Because it affects not only visual appeal but also structural integrity and customer satisfaction. This article reviews the occurrence of flow marks during insert molding, their causes, how to prevent them, and other best practices.

What Are Flow Marks in Insert Molding?

So, what exactly are flow marks? Sometimes called flow lines or flow patterns, they are visible surface defects that appear as wavy, streaky, or rippled lines on molded plastic parts. Generally, they are noticeable near gates, around embedded inserts, or along thin-walled sections of your molded part. These marks aren’t just cosmetic. They usually result from uneven cooling, inconsistent flow fronts, or variations in resin viscosity. In insert molding, where molten resin has to navigate tight spaces and flow around metal inserts, these flow disruptions are more likely. Thus, making proper control of the molding process critical.

Causes of Flow Marks in Insert Molding

Understanding the root causes of flow marks is the first step toward eliminating them. The following sections highlight some of these causes.

Shear Rate Fluctuations Around Inserts

Sudden flow path near inserts increases melt velocity (Bernoulli principle), causing shear-thinning. When this accelerated material impacts the insert surface, the velocity drops abruptly. The sharp deceleration compresses polymer chains into visible flow lines perpendicular to the flow direction, often appearing as tiger stripes on cosmetic surfaces.

Inadequate Melt Temperature

Low melt temperatures (near polymer crystallization point) reduce flow front mobility. When contacting cooler inserts, viscosity spikes instantly. This forces subsequent material to push through semi-solidified layers, creating laminar flow marks resembling tree rings.

Suboptimal Injection Speed

Slow injection speeds allow excessive cooling before cavity fill completion. Melt fronts solidify prematurely near inserts, causing new material to “fold over” stagnant layers. Fast speeds induce jetting that traps air against inserts. Both scenarios create a wavy surface pattern and microvoids at stress-critical interfaces.

Insert Geometry Complexity

Sharp insert corners or thick-thin transitions disrupt laminar flow. Turbulence forms recirculation zones where material overheats/degrades, while flow hesitation in recessed areas generates blotchy matte patches. Note that threaded inserts notoriously cause spiral flow marks due to helical flow path disruption.

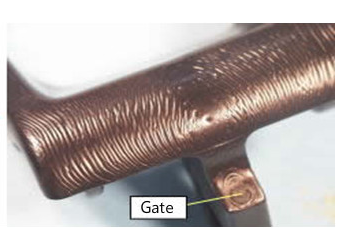

Flow Marks from Improper Gate Design or Location Relative to Inserts

Gates positioned far from the inserts cause excessive flow front cooling before reaching the metal components. Multi-gate systems with unbalanced flow paths create weld lines directly over inserts. Both scenarios produce flow marks, like in the image below, with structurally vulnerable zones. Thus, increasing the risk of insert pullout under load.

How to Prevent Flow Marks in Insert Molding

Optimize Insert Preheating

Flow marks during insert molding can be prevented through careful control of process parameters and mold design. One key method is optimizing insert preheating, where metal components are heated before molding to reduce thermal shock when contacting molten polymer. This maintains consistent material flow and prevents premature solidification at the insert interface, which is a primary cause of flow marks. The temperature must be precisely controlled, typically within ±5°C, using cartridge heaters or an induction system to ensure uniform heating without degrading the insert’s metallurgical properties or the polymer’s performance.

Dynamic Injection Speed Profiling

Injection speed profiling is another effective strategy to prevent flow marks. A multi-stage injection approach ensures optimal material flow, starting with high speed until the melt front nears the insert, then reducing speed (50-60%) while passing the insert to minimize shear stress, and finally increasing speed again to complete filling. Servo-electric machines with precise speed control help execute this strategy effectively, preventing hesitation marks while avoiding jetting or turbulence that could trap air near inserts.

Strategic Gate Placement to Avoid Flow Marks

Strategic gate placement is essential for uniform filling and avoiding flow marks. Gates should be positioned within 15mm of the insert’s edges to ensure consistent flow front advancement. Fan gates work well for wide inserts, while pinpoint gates are ideal for small cylindrical components. Hot runner systems improve control in multi-cavity molds. Mold flow simulation software, such as Moldflow, helps validate gate positioning before manufacturing the mold, ensuring balanced filling and preventing weld lines from forming over inserts, which can exacerbate flow marks.

Insert Surface Engineering

Surface treatment of inserts enhances polymer flow and adhesion while reducing flow marks. Micro-roughened surface improves mechanical interlocking, while thermal barrier coatings like ceramics minimize heat dissipation from the melt. Plasma or corona treatments can further enhance wettability for certain polymers. For threaded inserts, helical grooves help guide polymer flow smoothly, preventing flow hesitation and visible defects. These treatments ensure laminar flow and strong bonding while minimizing cosmetic imperfections.

Process Monitoring and Control

Real-time process monitoring and closed-loop control systems are crucial for maintaining consistency and preventing flow marks. IoT-enabled sensors track melt viscosity, insert temperature gradients, and cavity pressure at multiple points. Automated alerts flag deviations exceeding 5% from optimal parameters, allowing immediate adjustments. Machine learning algorithms can predict flow mark formation before defects appear, enabling proactive corrections. This data-driven approach ensures long-term process stability, reducing scrap rates and improving part quality in high-volume production.

Additional Best Practices to Avoid Flow Marks

Advanced Mold Temperature Control with Dynamic Zone Regulation

Implementing segmented mold temperature control with at least 3 independent zones (near-gate, insert area, end-of-fill) prevents flow marks by maintaining optimal thermal conditions throughout the filling process. The insert zones should be 10-15°C hotter than other areas to compensate for heat sink effects, using pulsed cooling circuits or cartridge heaters to achieve stability.

Polymer Flow Front Optimization Using Rheology-Modified Compounds

Specially formulated compounds with rheological additives alter flow dynamics to prevent flow marks. These additives create a low-friction slip layer at the mold wall while maintaining core viscosity, allowing the material to flow evenly past insert without the characteristic hesitation marks.

How ITD Precision Ensures Flow-Mark-Free Insert Molded Parts

Conformal Cooling Mastery

ITD Precision integrates conformal cooling channels precisely contoured to insert using DMLS/SLM, ensuring uniform heat removal that prevents flow mark inducing thermal gradients during overmolding.

Precision Injection Profiling

At ITD Precision their vertical Autojector molding platforms deliver multistage, servo-controlled injection speed and pressure profiling to maintain consistent resin flow around inserts, avoiding shear-related flow defects

High-Tolerance Tooling Design

With in-house CAD-CAM and CNC expertise, molds are built with optimized gate placement, smooth transitions, and balanced runners to ensure uninterrupted material flow and eliminate potential flow lines.

Real-Time Vision Inspection

AIAG CQI-23 compliant vision systems detect insert misplacement and surface anomalies during molding, enabling immediate process corrections to prevent visible flow mark formation.

Material Consistency Control

ITD Precision centralized material handling with gravimetric blending and dying ensures resin purity and consistent melt viscosity, which is essential for avoiding flow variations and cosmetic imperfections

ITD Precision Solution to Flow Marks

Flow marks go beyond cosmetic flaws, they are precision challenges that affect performance, structural integrity, and durability of insert-molded parts. From insert preheating and melt temperature control to tooling design, every parameter matters. ITD Precision’s advanced molding expertise, precision tooling, and integrated quality systems make us the partner of choice for flawless, high-performance components. For the best results on your insert molding projects, Contact Us today.