EXCELLENCE IN MANUFACTURING

Creating and Sustaining a Culture of Excellence

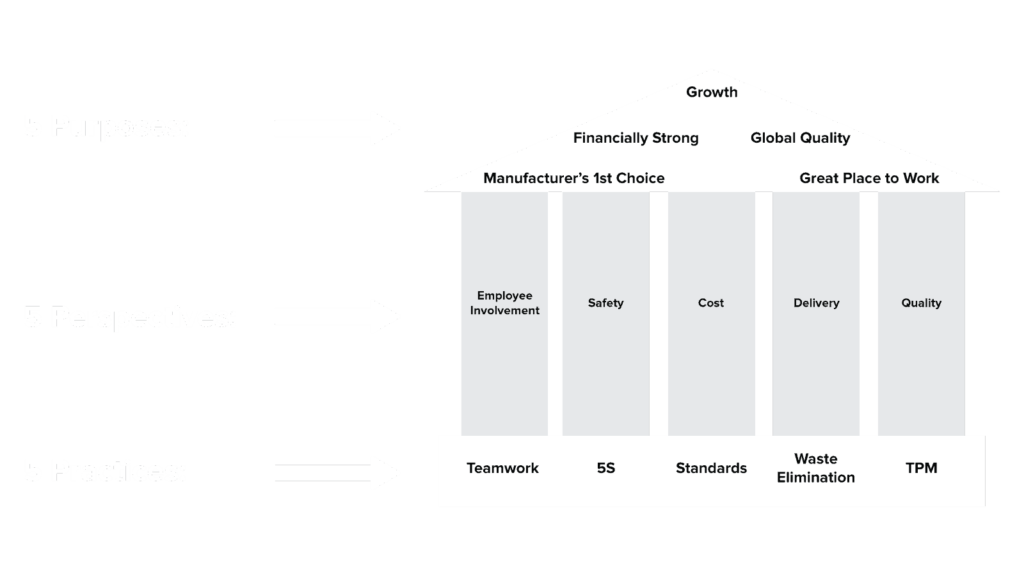

In 2012, ITD Precision formulated it’s Continuous Improvement Initiative modeled after the Toyota Production System for deployment of lean manufacturing practices and principles. We call it “Excellence In Manufacturing,” or EIM. To achieve our 5 Purposes, we observe our performance from 5 Perspectives, and employ the 5 Practices (tools) for elimination and prevention of waste.

Our 5 Purposes

The foundation of our EIM initiative is built on five core purposes:

- Growth: We aim for continuous growth, hence, ensuring our company remains competitive and innovative.

- Financial Strength: Maintaining strong financial health allows us to invest in new technologies, training, as well as development.

- Global Quality: We are dedicated to delivering products that meet global quality standards, ensuring customer satisfaction worldwide.

- Manufacturer’s First Choice: Our goal is to be the preferred partner for manufacturers, providing reliable and also high-quality solutions.

- Great Place to Work: We strive to create a workplace environment that fosters teamwork, innovation, and employee satisfaction.

Our 5 Perspectives

To achieve these purposes, we observe our performance through five critical perspectives:

- Employee Involvement: Engaging our employees at all levels to contribute to continuous improvement.

- Safety: Prioritizing a safe work environment to protect our most valuable assets—our employees.

- Cost: Focusing on cost management to enhance efficiency and also profitability.

- Delivery: Ensuring timely delivery of products to meet customer demands.

- Quality: Committing to superior quality in all our processes and products.

Our 5 Practices

The EIM initiative employs five key practices, or tools, to eliminate and prevent waste:

- Teamwork: Encouraging collaboration and collective problem-solving to drive improvements.

- 5S: Implementing the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain) to maintain an organized, as well as efficient workplace.

- Standards: Establishing and adhering to standards to ensure consistency and reliability in our processes.

- Waste Elimination: Continuously identifying and eliminating waste to streamline operations.

- TPM (Total Productive Maintenance): Enhancing equipment reliability and productivity through proactive maintenance practices.

Achieving Excellence in Manufacturing

The synergy of these purposes, perspectives, and practices forms the bedrock of ITD Precision’s pursuit of manufacturing excellence. Our continuous improvement efforts are driven by a culture that values innovation, quality, and also customer satisfaction. By integrating these principles into our daily operations, we not only enhance our performance but also ensure the sustainable growth and success of our company.